Educational Innovation: ISyE junior design course uses blended learning and lego kits to teach fundamental skills of design

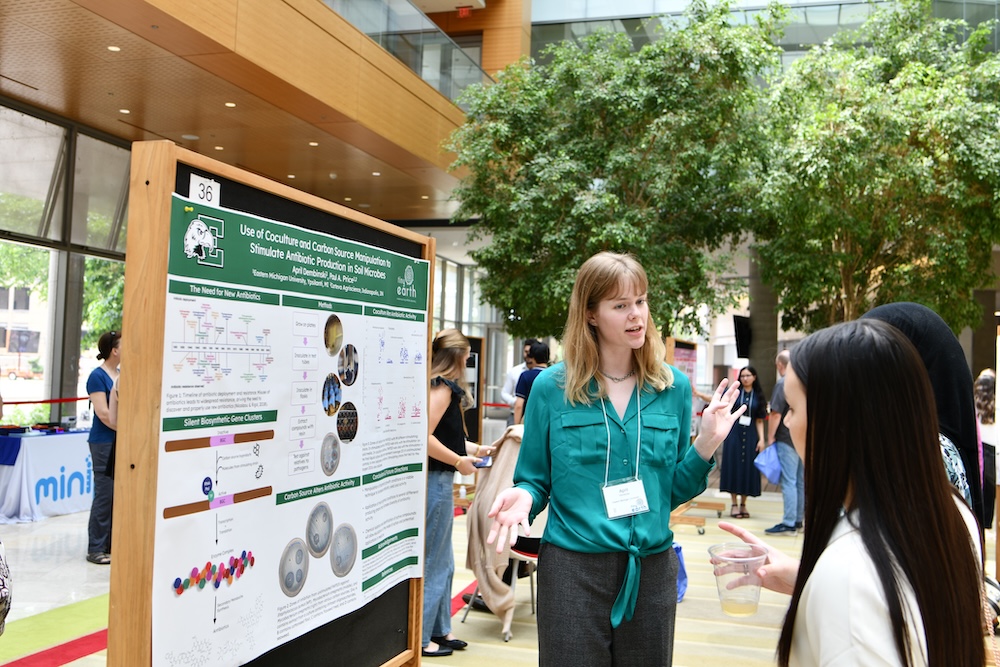

Robert Radwin

Senior design courses are often the most crucial learning experience in an engineering student’s undergraduate career. However, industrial and systems engineering instructors have noticed that students sometimes struggle to finish their projects within the time constraints of the semester, often because they bring widely different skill sets to the course.

Enter ISyE 350, a lab-based course that gives industrial and systems engineering juniors a full design experience, but also provides them the full range of knowledge and experiences they will need to be successful in their senior capstone design course.

At the beginning of the semester, juniors are split into teams based on their varying skillsets. They receive a LEGO® MINDSTORMS® robot kit, which includes a microcomputer, servos, monitors, conveyor belts and other tools that students might need to assemble their project.

Every semester, Professor Rob Radwin, who developed and teaches the course, presents students with an open-ended problem to tackle, using the materials provided in the LEGO kits.

In fall 2015, their client was a fictitious online dairy company fulfillment center, and their challenge involved incoming online orders of cheese that needed to be packaged at different stations and shipped out to the right customers. Each team had to design an automated system, which involved analyzing, developing, programming and constructing a working model of their design for the client, who presumably would select the best design.

“It’s very complex: They have to take in orders, design an algorithm that’s going to be efficient, and not make errors,” Radwin says. “Everyone has a different approach—each group comes up with a different way of doing the same problem, and then they have to try to prove their method is the best.”

One team developed a series of ramps that would deliver the cheeses, represented by small blocks, to their appropriate locations. Team member Logan Dirkx says that their design, which involves a rotating funnel, is the most cost-effective and efficient way of approaching the problem. “The most important factor was having everything be dispersed concurrently,” Dirkx says. “This naturally led to a ramp system, which allowed us to funnel everything from one location.”

In his team’s solution, the cheeses all pass through a funnel and then separate, programmed ramps rotate to deliver each cheese to the correct location. The funnel allowed them to use gravity to their advantage, since the ramps angle down from the funnel.

Dirkx and his teammates found the class worthwhile and say it provided them hands-on experience without the high-stakes pressure of the penultimate senior capstone course.

In ISyE 350, students have the entire semester to develop their prototype, which often requires learning new skills. For instance, in order to program the system to deliver orders to the correct stations, the students use the programming language Robot C. Although most ISyE students have taken at least one programming course, ISyE 350 requires that they directly apply these skills to a real-life situation.

In the course, Radwin uses blended learning, the concept of using digital media for teaching purposes, to present students the conceptual ideas and design tools they will need to move forward with their design projects. The night before the course meets, they can access online lectures, which cover topics such as measuring a customer’s needs, concept generation, or systematically evaluating the best design, then attend class the next day with the fundamental knowledge they need to solve a very tangible problem.

Students use a variety of additional materials—including duct tape and cardboard cereal boxes—to construct their prototypes, and two-thirds of the way through the fall semester, many had finished their prototypes and were working out the kinks required to get their system working smoothly.

And while LEGOS, duct tape and cardboard arguably are rather low-tech materials, they are everyday tools that help the students master higher-level concepts. “This semester is the most complex problem I’ve given them,” Radwin says. “And the students already have working prototypes, which is the earliest students have completed them in this course, which is in its third year. Even though we seem to be making the problems harder and harder each semester, they’re actually getting better at doing this.”

Lexy Brodt

1/19/2016

This article originally appeared on the College of Engineering Website