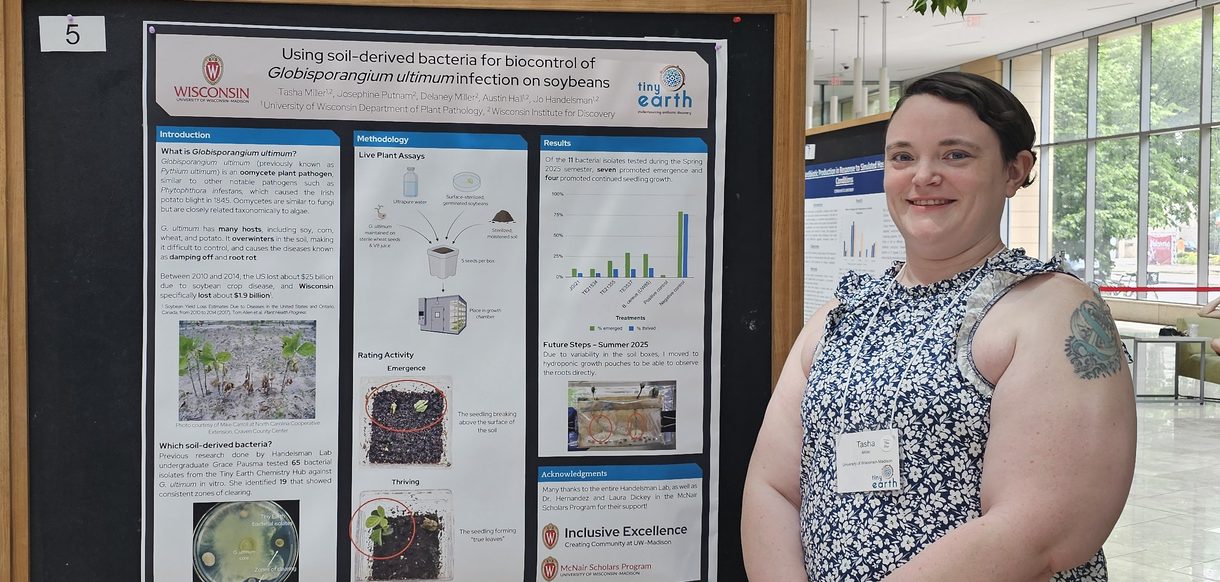

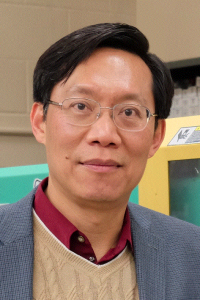

Professor Lih-Sheng (Tom) Turng: Advancing Microcellular Polymers

Thanks to the research of Professor Lih-Sheng (Tom) Turng, plastics can have applications in products ranging from eyeglass lenses to engineered tissues.

Within the Department of Mechanical Engineering and the Wisconsin Institute for Discovery at the University of Wisconsin-Madison, Turng studies areas that include injection molding, microcellular injection molding, nanocomposites, biobased polymers, and tissue engineering scaffolds—and this research is redefining the future of polymers in industry, the environment, and public health.

Born and raised in Taiwan, Turng received his bachelor’s degree in mechanical engineering from the National Taiwan University with a minor in manufacturing, and his master’s and PhD degrees from Cornell University. At Cornell, he worked in the Cornell Injection Molding Program (CIMP). He also worked in industry, developing advanced plastics injection molding simulation software and a knowledge management system for 10 years before joining the University of Wisconsin–Madison in 2000. At UW–Madison, Turng chose to work on microcellular plastics. His research spans three distinct fields, as shown below.

Polymer processing and engineering

Prof. Lih-Sheng Turng with a multi-functional microcellular and co-injection molding machine

Microcellular injection molding is a process that produces dimensionally stable and lighter weight plastic products featuring numerous microscale voids that reduce part weight by replacing plastics with gas. This manufacturing process uses less energy, offers additional design freedom, and costs less to make and ship. Products produced with these qualities are highly sought after in the aerospace, automotive, business equipment, and sporting industries, and have found emerging applications as mass-produced tissue engineering scaffolds with an interconnected pore structure and complex geometry.

Nanocomposites and nanotechnology

One thousand times thinner than a human hair, nanoscale fillers are incorporated into certain types of polymers to improve their mechanical properties, rigidity, and electrical conductivity, and in some cases, to retain transparency in the final product. These nanoscale fillers also serve as nucleating agents, helping to enhance the microstructure and mechanical performance of microcellular injection molded nanocomposites. The tunable physiological properties of nanocomposites also render them perfect candidates for a wide variety of advanced applications including tissue engineering scaffolds for matching properties with host natural tissues.

Biobased plastics and composites

This research deals with plastics made of sustainable and renewable resources (like corn starch or agricultural byproducts) or natural polymers and then improves their performance through blending and compounding. Depending on the type of plastic and composting conditions, these plastics can be customized to biodegrade over a certain period of time. In addition to being great materials for packaging applications and compostable agricultural products, the biodegradability and biocompatibility of biobased plastics/composites gives them great potential in biomedical applications.

“As you can see, combining multiple research areas yields innovative ideas and novel concepts.”

-Lih Sheng (Tom) Turng

Turng and his team realized, by drawing on expertise in engineering and the life sciences and combining these research topics, he could pursue yet another important research area: tissue engineering. That is, he and his team can mass produce porous tissue engineering constructs (as the scaffolds) using microcellular injection molding with biodegradable and biocompatible plastics whose properties can be fine-tuned to match those of the host tissue using nanocomposite technology. This led to the BIONATES theme (BIO-NAnocomposite Tissue Engineering Scaffolds) in the Wisconsin Institute for Discovery (WID), of which he is the theme leader. This team develops innovative tissue engineering scaffolds and bioreactors that grow cells and control their behavior into functional cell masses or tissues for medical research and drug testing. “Had we only focused on one of our research areas—polymer processing and engineering, nanocomposites and nanotechnology, or biobased plastics—we would not have had this opportunity to realize the potential synergy among multiple research areas and participate in a multidisciplinary research study at WID,” says Turng. “We are now in a very good position to tackle and produce multi-functional tissue engineering scaffolds in collaboration with our cell and developmental biology collaborators. So, as you can see, combining multiple research areas yields innovative ideas and novel concepts.”

Turng’s advice to students considering entering the materials science field highlights three areas: multidisciplinary research, open-mindedness, and collaboration. According to Turng, these principles will bring success to future materials scientists and engineers. He also notes: “Maintain a “can-do” attitude and try to do good work with your own research, but keep an open eye on other technologies, then good things will happen naturally. Major discoveries always happen at the intersection of different disciplines.”

For more information on Turng’s work, please see:

Originally posted on February 11, 2016 on the Wisconsin Materials Institute website by sely@cae.wisc.edu