‘Smart’ Medical Material Aims to Unfurl at 98.6 Degrees

Lih-Sheng (Tom) Turng, professor of Mechanical Engineering and leader of WID’s BIONATES research area, has a simple office demonstration of how shape-memory polymers work. He takes the material, which is formed into a compact flower bud, drops the bud in a cup of warm water, and voila: A daisy slowly blooms.

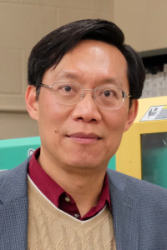

Tom Turng

A significant materials research advance by Turng and colleagues may help translate this shape-shifting phenomenon to human medicine. Turng and Ph.D. students Hao-Yang Mi and Xin Jing have discovered a new blend of shape-memory polymer that can regain its predetermined shape when exposed to heat levels close to human body temperature. This could have exciting implications for surgical implants such as stents and artificial arteries, which could be implanted in compact form and regain their desired shape naturally in the body.

“This material has some amazing recovery properties,” says Turng. “Our ultimate goal is to create shape-memory materials that will regain their permanent shape at human body temperature.”

Shape-memory polymers have been around since the 1980s but currently require too high a temperature trigger to have widespread use in medicine. However, Turng’s polymer blends unfurl from a temporary spiral shape to a memorized permanent straight shape at 158 degrees Fahrenheit. While the goal will be to get the reaction to occur at 98.6 degrees Fahrenheit, the temperatures are significantly lower than the current state of the art.

“Right now, we’re looking for the best combination of materials that will bring down the transition temperature,” says Hao-Yang Mi.

The research team uses inexpensive polymer materials commonly used in injection molding environments. The key is combining a mix of polymers with both brittle and elastic properties. The mix used here is amorphous polylactic acid, derived from corn starch, and thermoplastic polyurethane, a stretch plastic commonly found in athletic apparel.

In addition to the transition temperature, the researchers are working to improve their materials’ overall strength for medical applications. They also are following a variety of other promising paths, including using stem cells in tissue scaffolding and on drug delivery applications embedded within the shape-memory materials.

— Brian Mattmiller, UW-Madison College of Engineering