Heavy lifting is a leading cause of workplace injuries, which, according to the Bureau of Labor Statistics, can include nerve pain, strains, and spine injuries. A new group housed in the Wisconsin Institute for Discovery (WID) at the University of Wisconsin–Madison is working to address challenges like this by researching how to better integrate robots into the manufacturing industry and beyond.

Heavy lifting may seem like a simple job, but it requires human intuition and intelligence. That means transferring lifting to robots demands a multifaceted approach. Enter the INTEGRATE project, a group seeking interdisciplinary solutions to the psychological and technical challenges of integrating robots into the workplace.

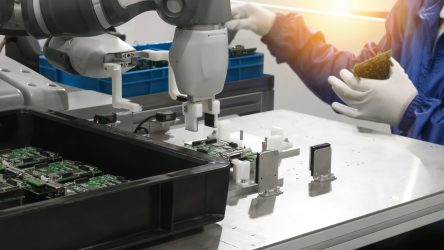

One example is cobots, or collaborative robots. These robots are smaller, slower, and designed to work safely alongside humans in several workplace settings. Unlike industrial machines, which require a safety cage to protect human workers from injury, cobots can work in closer collaboration with people. There is a huge demand for cobots not only in manufacturing, but also in science, where they can assist in repetitive processes such as mixing solutions or managing samples. However, some companies are hesitant to blend man and machine in this capacity.

Led by Program Director Bilge Mutlu, the INTEGRATE Project is an interdisciplinary group that combines expertise from computer sciences, economics, engineering, psychology, and robotics. Since the group’s inception in fall 2022, INTEGRATE’s overall mission has been to educate a new group of researchers who can collaborate across different fields to influence the development of robotic technology and shape the way work is done in the future.

One of the most challenging obstacles to integrating cobots into various industries is psychological resistance to using robots. Accustomed to being sequestered from cobots, wary of not-uncommon workplace injuries, and habituated by decades of working another way, workers are understandably resistant to cobots.

The INTEGRATE team’s research combines social and physical sciences to better understand workers’ sentiments toward robots in the workplace, focusing on fear of job displacement, building trust and a positive coexistence between workers and robots. Rather than replacing human workers, the goal of cobots is to complement and assist them in various tasks–a process that presents its own challenges. Adapting to the specific needs of a worker creates programming challenges for the robotics designers and might create or worsen a skills gap for the worker. In the next step of the program, the INTEGRATE team will send researchers on expeditions into the workforce to provide technical expertise as companies integrate cobots into the workforce.

“While companies have an interest in exploring these options, many don’t have the technical expertise to do so,” says Andrew Schoen, a graduate student trainee in INTEGRATE. “While there is a plethora of research in the academic domain about how collaborative robots can be used in truly collaborative ways, we haven’t seen really good penetration of these methods into the actual industries.”

INTEGRATE, short for “Integrating Robots into the Future of Work,” is a National Science Foundation Research Traineeship (NRT) program built around the premise that robotic integration is not a singular concept but encompasses three main categories: automation, robotics, and collaborative robotics.

Automation focuses on streamlining and automating processes in various workflows, including mechanical automation and quality/process monitoring. Recent advancements incorporate intelligent decision-making based on connected devices. Robotic automation, the second category, involves the use of large, precise robots for specific repetitive tasks such as lifting heavy machinery or forming parts. The third category is cobots. They present an opportunity to complement human workers in tasks that require human intuition or expertise, while still addressing ergonomic or worker preference concerns.

“Collaborative robots have potential applications beyond factory work,” says Schoen, “from repetitive scientific tasks like mixing solutions or managing samples to attaching cobots to wheelchairs for assistive purposes such as feeding, where the human requests and receives food from the robot.”

Furthermore, cobots could improve employee retention rates. Schoen says, “The more ergonomic and safe the job is, the less demanding it is, the fewer the injuries, and the less expense that the company may have to pay out (e.g. insurance and possible downtime). You can see why companies would want to consider ways to make these jobs better for people.

In addition, INTEGRATE will help prepare students for the research challenges of integrating robotics into future workplaces by using four core components:

- Personalized curriculum. Students will be able to choose between five concentrations that will help to broaden their understanding of connections between STEM training and human-centered disciplines.

- Expeditions. Year-long team research projects on real-world problems.

- Professional development. Internships and secondments.

- INTEGRATE research community. Regular colloquiums, and an annual symposium.

Upon completion of the trainee program, graduate students will receive a graduate certificate degree in “integrative robotics” along with hands-on, immersive research experiences that will help them form partnerships with industries for future collaborative projects.

Mutlu thinks INTEGRATE is a unique, interdisciplinary program that can train graduate students to consider both the technical and societal challenges of introducing cobots into the workplace.

“We are approaching the problem of integrating robots into workplaces from multiple angles, including robotics, psychology, and economics,” Mutlu explains. While INTEGRATE is only one part of UW-Madison’s efforts to expand research on the technical and societal effects of robotics, he believes this interdisciplinary approach has the potential to inform how cobots are designed, adopted by industry, and become day-to-day technologies we all rely on.

Trainee nominations for the 2023-2024 academic year are now being accepted until October 4, 2023.

–Keegen Kuehne

You must be logged in to post a comment.